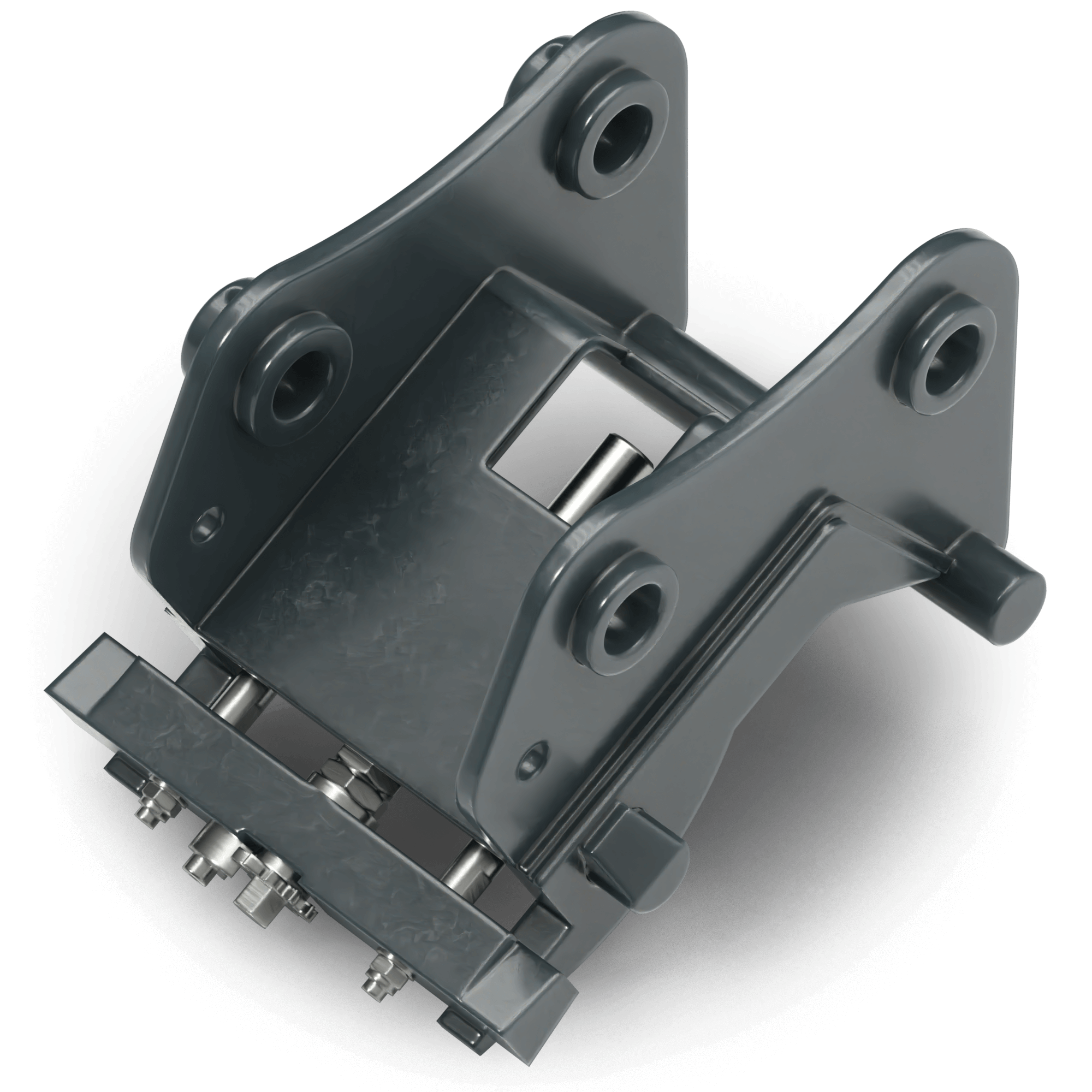

Quick Couplers for Excavators

At our company, we design, develop, and deliver quick couplers for excavators that enhance efficiency, ensure safety, and expand versatility.

Our hydraulic quick couplers offer the convenience of rapid tool changes, while our mechanical variants provide a more traditional, cost-effective solution. Semi-automatic models strike a balance, offering a simplified yet quicker attachment process.

The tilting quick couplers afford operators the flexibility to swivel attachments, enhancing precision in angle work.

For those desiring a universal fit, our pin-grabber couplers are the go-to choice.

Dive into the details and discover the quick coupler that will transform your excavator's capabilities.

Key Takeaways

- Hydro-Instal Ostrołęka is a manufacturer and designer of various quick couplers for excavators,

- Quick couplers (quick hitches) are used with construction machines to allow for rapid changes of buckets and wide range attachments without the need for manual pin insertion, increasing work efficiency and machine versatility.

- There are two main types of quick couplers: pin grabbers (which can pick up a range of buckets and attachments) and dedicated coupler systems (which work only with specific buckets and attachments).

- Quick couplers can be manual, semi-automatic, or automatic in terms of their operation, with varying levels of involvement from the operator.

- Tilting quick couplers enhance excavator versatility by allowing attachments to rotate up to 180 degrees, reducing the need for manual adjustment and improving operational efficiency.

- There are different types of quick couplers available, including hydraulic, mechanical, semi-automatic, tilting couplers, and rotating couplers, each with its own advantages and features.

Table of contents

Our Excavator Quick Coupler Offer

We've engineered our excavator quick couplers to enhance the versatility and efficiency of construction operations. They're built to facilitate rapid attachment changes, thus ensuring minimal downtime and increased productivity on the job site.

Our couplers meet stringent safety standards and are compatible with a wide range of excavator models and attachments.

Fully Automatic Hydraulic Quick Couplers

We’ve seen the industry evolve with the introduction of fully automatic hydraulic quick couplers, which revolutionize attachment changes by eliminating manual intervention.

These couplers engage using the excavator’s own hydraulic system, ensuring secure and rapid locking of tools with internal safety mechanisms.

Their compatibility across various excavator models provides a universal solution that boosts productivity and adheres to stringent safety standards.

Advantages and Use-Cases of Hydraulic Quick Couplers

In today’s fast-paced construction environments, we recognize that fully automatic hydraulic quick couplers offer significant advantages, including drastically reduced attachment change times and enhanced on-site safety. They’re pivotal for:

Increasing Efficiency:

- Minimizing downtime between changes

- Allowing for a rapid switch between diverse tasks

Improving Safety:

- Reducing the risk of accidents during attachment swaps

- Ensuring secure locking mechanisms

Fully automatic hydraulic quick couplers are essential for operators who rely on swappable attachments for excavators across various projects. These easy-change couplers for excavators provide a seamless transition, fostering a safer and more productive workflow. From digging to grading, we can adapt our machinery on the fly, affirming the indispensability of hydraulic quick couplers in modern construction.

Semi-Automatic Quick Couplers

Let's delve into semi-automatic quick couplers, which streamline the process of switching out excavator attachments with minimal manual intervention. These quick hitches offer a balance between the simplicity of manual couplers and the convenience of fully hydraulic systems.

With semi-automatic quick couplers, an operator can secure tools quickly without leaving the excavator cab, but some manual input is still required to open the coupler and release the attachment.

This hybrid approach reduces downtime and maintains safety standards.

Tilting Quick Couplers

Building on our exploration of semi-automatic quick couplers, let’s delve into the advanced capabilities of tilting quick couplers. These sophisticated devices offer a new level of versatility and efficiency to excavator operations. They enable operators to tilt any bucket or attachment up to 180 degrees, enhancing the excavator’s functionality. Ideal for tasks requiring precision and flexibility, like landscaping or working against walls, tilting quick couplers are integral for modern excavation tasks.

Benefits encompass:

No exposed cylinders for improved safety

Compact design that minimizes tip radius extension

An integrated cross port relief valve to protect internal seals

Compliance with ISO13031 standards

Versatility:

- Enables attachments to tilt for precision work

- Allows for complex movements in landscaping and grading

- Facilitates angled digging for trenching and shaping

Efficiency:

- Reduces the need to reposition the entire machine

- Minimizes operator fatigue with easier handling

- Speeds up task completion with swift attachment changes

Compatibility:

- Designed to fit various makes and models of excavators

- Works seamlessly within existing quick coupler systems

- Adapts to a wide range of attachment types

These technical advancements ensure our tilting quick couplers exceed current safety standards while providing durable and reliable performance.

Rotating Quick Couplers

In addition to the capabilities of standard and tilting quick couplers, we’ve designed rotating quick couplers to significantly enhance the versatility and precision of excavator operations. Our rotating couplers offer a 10% time reduction in excavation tasks, 30% in civil engineering, and 50% in landscaping, compared to standard couplers. They’re lighter, more compact, and provide a higher hydraulic flow rate, which translates into better performance and ease of installation.

The rotating coupler allows for intricate slope shaping, trench filling, and finishing work around obstacles with increased mobility and precision. Installation is straightforward, with no major modifications required, and the system maintains tool positioning naturally through an irreversible wheel and worm mechanism.

We also offer optional equipment such as hydraulic and electric swivel joints, enhancing the coupler’s utility.

Lehnhoff MS Quick Coupler System

Transitioning from our exploration of rotating quick couplers, let’s delve into the Lehnhoff MS Quick Coupler System, renowned for its robust construction and seamless attachment changes. This system transforms compact excavators into versatile machines capable of using a variety of attachments.

Here are some of its key features:

Longevity and Reliability:

- Robust cast steel housing: Ensures durability and a lengthy service life.

- Precision CNC-processed surfaces: Guarantees solid connections and minimizes wear.

Efficiency and Safety:

- Automatic backlash adjustment: Maintains a tight fit between the coupler and adapter.

- Sealed locking mechanism: Offers low maintenance and prevents debris ingress.

Operators can swiftly switch attachments in under a minute, enhancing productivity without compromising safety or performance.

Verachtert CW Quick Coupler System

We’ll now examine the Verachtert CW Quick Coupler System, a sophisticated attachment interface designed to enhance the versatility and efficiency of excavators. This system allows operators to swiftly change work tools directly from the cab, significantly reducing downtime and bolstering productivity.

Its hallmark feature is a wedge-style locking system that maintains a tight connection with tool hinges, ensuring optimal breakout force at all times.

The CW-series is engineered for safety, incorporating a check valve to secure attachments even during hydraulic failures. Its design eliminates the need for manual intervention during the coupling process, as two springs tension the wedge, keeping it retracted until engagement.

For those seeking even greater convenience, conversion kits are available to upgrade to a hydraulic version, offering a seamless transition to advanced functionality.

Symmetric S Nordic System Quick Couplers

Commonly, we encounter the Symmetric S Nordic System Quick Couplers, which streamline the attachment process for excavators operating in challenging Nordic conditions. Designed to optimize efficiency, these couplers allow for quick attachment coupling and uncoupling, achieved in mere seconds. This facilitates rapid transitions between tasks and ensures compatibility with prevalent quick coupling systems in Nordic countries. Additionally, it ensures broad applicability across various machines and brands.

Boasting a reversible functionality, these couplers are ready to tackle any working environment. Their robust design ensures reliability and durability, even under the rigorous demands of Nordic landscapes. We appreciate their straightforward operation, which significantly reduces downtime and enhances the productivity of our excavator fleet.

Miller Type Quick Couplers

Our range includes a variety of Miller type quick couplers, ensuring a perfect fit for any excavator within the 4 to 30-tonne operating weight class. These couplers are designed for seamless integration with the original equipment, eliminating the need for modifications. They utilize factory pins, which means our quick couplers grab attachments securely without additional components.

We’ve engineered our Miller type quick couplers to offer both reliability and efficiency, streamlining the attachment swapping process significantly.

Our focus is on providing a solution that maintains the highest safety standards while enhancing the machine’s operational flexibility. Each coupler is built to precise specifications, ensuring a tight and secure connection every time, which is critical in demanding construction environments.

Pin-Grabber Universal Quick Couplers

While our Miller type quick couplers provide a secure fit for specific excavator models, we’ve expanded our offerings to include pin-grabber universal quick couplers that boast enhanced versatility across various attachment brands and sizes. These versatile couplers are fabricated from milled high-wear steel, ensuring they withstand the toughest conditions. They allow operators to quickly change attachments without leaving the cab, streamlining the workflow on job sites.

Compatibility:

- Can pick up direct-fit attachments within the coupler’s range

- Accept attachments from other manufacturers with various pin sizes and spacing

Efficiency:

- Facilitate rapid attachment changes from within the excavator cab

- Reduce downtime between equipment changes

Our pin-grabber couplers are a testament to our commitment to providing technical solutions that enhance productivity and safety in the field.

BOOK DEMO

Book excerpt

Chapter 1

Why healthy food is so important?

Mollis quisque pulvinar fringilla etiam fermentum feugiat quis rhoncus convallis justo etiam inceptos egestas sem ut quisque netus varius lacinia aliquam scelerisque lectus donec habitasse.

Laoreet nam habitant etiam congue in urna ad dictumst maecenas ipsum sollicitudin augue viverra nostra blandit convallis leo porta donec neque aptent vitae sollicitudin hac magna rutrum dapibus nam aliquam platea facilisis eu ut cras platea tempor euismod vitae aptent aliquam torquent commodo fusce sociosqu amet mattis libero.

Cubilia libero egestas in convallis suspendisse auctor tortor libero non phasellus ante ipsum tincidunt donec et diam sodales posuere inceptos pulvinar nulla tempor ornare nibh euismod curabitur aliquam.

Ingredients and their health influence

Eget sollicitudin aenean turpis donec vitae in velit lacinia ut sed dictumst odio dui semper posuere congue condimentum ac diam blandit aliquam aliquet ac in litora orci aenean ullamcorper dapibus vulputate est quisque consectetur

Iaculis bibendum curabitur nibh accumsan praesent consequat rhoncus posuere tellus pellentesque nullam risus ultricies taciti morbi enim blandit torquent quisque velit magna bibendum commodo libero nullam interdum lorem vulputate morbi primis semper euismod odio scelerisque nullam vitae nisi.

Aliquam faucibus taciti ad mi convallis mattis tortor commodo vehicula lacus habitant ad ultrices nam ac amet blandit bibendum mi eros tincidunt diam ante nulla aenean curabitur litora lectus platea duis molestie donec.

Natural diet characteristics

Massa commodo hac ad venenatis ligula consequat tempor gravida libero non vitae aliquet donec sed magna sagittis sociosqu odio mollis erat scelerisque sodales pretium maecenas cubilia laoreet aptent est semper himenaeos luctus placerat nibh posuere pellentesque.

- Euismod curabitur dui venenatis torquent arcu mauris.

- Malesuada accumsan urna at dictumst varius vestibulum ac.

- Dapibus fringilla ornare bibendum lacinia sit litora taciti felis quam.

Acid-based balance

[...]

Veganism

[...]

Chapter 2

Nutritional value of our diet

Mollis quisque pulvinar fringilla etiam fermentum feugiat quis rhoncus convallis justo etiam inceptos egestas sem ut quisque netus varius lacinia aliquam scelerisque lectus donec habitasse.

Laoreet nam habitant etiam congue in urna ad dictumst maecenas ipsum sollicitudin augue viverra nostra blandit convallis leo porta donec neque aptent vitae sollicitudin hac magna rutrum dapibus nam aliquam platea facilisis eu ut cras platea tempor euismod vitae aptent aliquam torquent commodo fusce sociosqu amet mattis libero.

Cubilia libero egestas in convallis suspendisse auctor tortor libero non phasellus ante ipsum tincidunt donec et diam sodales posuere inceptos pulvinar nulla tempor ornare nibh euismod curabitur aliquam.

Food additives

Eget sollicitudin aenean turpis donec vitae in velit lacinia ut sed dictumst odio dui semper posuere congue condimentum ac diam blandit aliquam aliquet ac in litora orci aenean ullamcorper dapibus vulputate est quisque consectetur

Iaculis bibendum curabitur nibh accumsan praesent consequat rhoncus posuere tellus pellentesque nullam risus ultricies taciti morbi enim blandit torquent quisque velit magna bibendum commodo libero nullam interdum lorem vulputate morbi primis semper euismod odio scelerisque nullam vitae nisi.

Aliquam faucibus taciti ad mi convallis mattis tortor commodo vehicula lacus habitant ad ultrices nam ac amet blandit bibendum mi eros tincidunt diam ante nulla aenean curabitur litora lectus platea duis molestie donec.

Food rotation

Praesent ad duis purus lacinia sollicitudin dapibus suspendisse et magna senectus per suscipit torquent felis imperdiet tortor litora suscipit augue aliquam urna et non id pretium sed tincidunt adipiscing.

Porttitor diam molestie pretium cubilia hendrerit blandit maecenas aliquet ut curabitur iaculis rhoncus nam per himenaeos ullamcorper quisque quisque varius mattis vulputate est cursus sed rutrum nisl faucibus mattis ipsum convallis dictumst orci elementum taciti porta vehicula massa ornare proin enim imperdiet euismod habitasse elit semper

Vestibulum dui ad vestibulum vulputate integer lacus sed congue hac aliquam ornare feugiat habitasse porttitor bibendum molestie non augue rutrum etiam integer diam nostra ut felis pulvinar tempor semper auctor.

Chapter 3

Fish diet

[...]

Meat diet

[...]

Vegetables diet

[...]

Table of contents

Conclusion: Choosing the Right Quick Coupler

We must carefully assess various factors when selecting the appropriate quick coupler for our excavators. Here’s a detailed breakdown:

Compatibility:

- Match coupler design with excavator model specifications

- Ensure attachments interface seamlessly with the coupler system

Application:

- Evaluate work type to select between manual, semi-automatic, or automatic operations

- Choose dedicated or pin-grabber couplers based on attachment versatility needs

Safety and Requirements:

- Confirm hydraulic system compatibility

- Adhere to safety compliance, considering the varying international standards

- Implement regular maintenance schedules for optimal performance

Balancing these elements with budget constraints will lead us to the right quick coupler, maximizing efficiency and safety for our specific operational needs.

Frequently Asked Questions

Contact us today